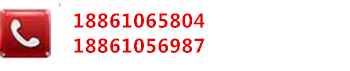

联系我们

电话:0523-83785508

传真:0523-83885226

联系人:孟祥思

地址:江苏省兴化市戴南镇陈祁工业园

新闻动态

什么原因导致304不锈钢铸件带有微磁性

什么原因导致304不锈钢铸件带有微磁性

1、化学成分当量成分控制没有到位。1. The control of chemical equivalents is not in place.

一般的生产厂家为了降低成本把Ni控制下限,8.0-8.2%之间,Cr/Ni达到一定数值时钢的组织中出现一定量的铁素体,铁素体是有磁性的;此时采用1050~1080℃固溶处理可以把铁素体完全溶入奥氏体就不会有磁性了。

In order to reduce the cost, the general manufacturer controls the lower limit of Ni. Between 8.0% and 8.2%, when Cr/Ni reaches a certain value, a certain amount of ferrite appears in the structure of steel, and the ferrite is magnetic. At this time, the ferrite can be completely dissolved into austenite by solid solution treatment at 1050-1080 C, and there will be no magnetism.

2、冷加工硬化。

2. Cold work hardening.

当奥氏体不锈钢在冷加工时产生形变马检查井钢模具 隔离墩模具 隔离墩钢模具 流水槽模具 U型槽模具 螺杆启闭机 卷扬式启闭机 铜雕佛像氏体,形变马氏体使得不锈钢强度增加,而形变马氏体是有磁性的。采用固溶处理甚至退火都可以使形变马氏体消失,但是钢的强度就会下降了。

Deformed martensite occurs in austenitic stainless steel during cold working. Deformed martensite increases the strength of stainless steel, while deformed martensite is magnetic. Deformed martensite can be eliminated by solution treatment or even annealing, but the strength of steel will decrease

阿里巴巴

阿里巴巴